Prototyping

3D printing

Tolerance analysis

Test rig building

Realising

Procurement with Chinese suppliers

Cost analysis

BOM creation

Data management

Technical drawing

Research

Market research

Standards interpretation

Ideating

Design

Design for manufacture

Design for assembly

Iterating

Modelling

Solid modelling (SolidWorks)

FEA (SolidWorks)

Rendering (PhotoView 360)

The Brief

“Following the Grenfell tragedy of 2016, it is necessary to design a new type of cladding system that can be retrofit onto existing buildings and is fire resistant. The system should be mostly extruded pieces for cheaper manufacture, and as few pieces as possible reduce the number of moulds that need to be opened. It should be easily adaptable to different situations and easily installed.”

Initial Sketches

When designing the geometry of the system, I began with sketches to help me understand how the shapes would fit together. This was later used in tandem with 3D modelling to refine and develop the design.

3D Modelling

Many concepts were then modelled in 3D to see how all the pieces might fit together in a 3D space. Modelling this way made it clearer what would and wouldn’t work in different situations, enabling different concepts to be slowly combined and improved upon.

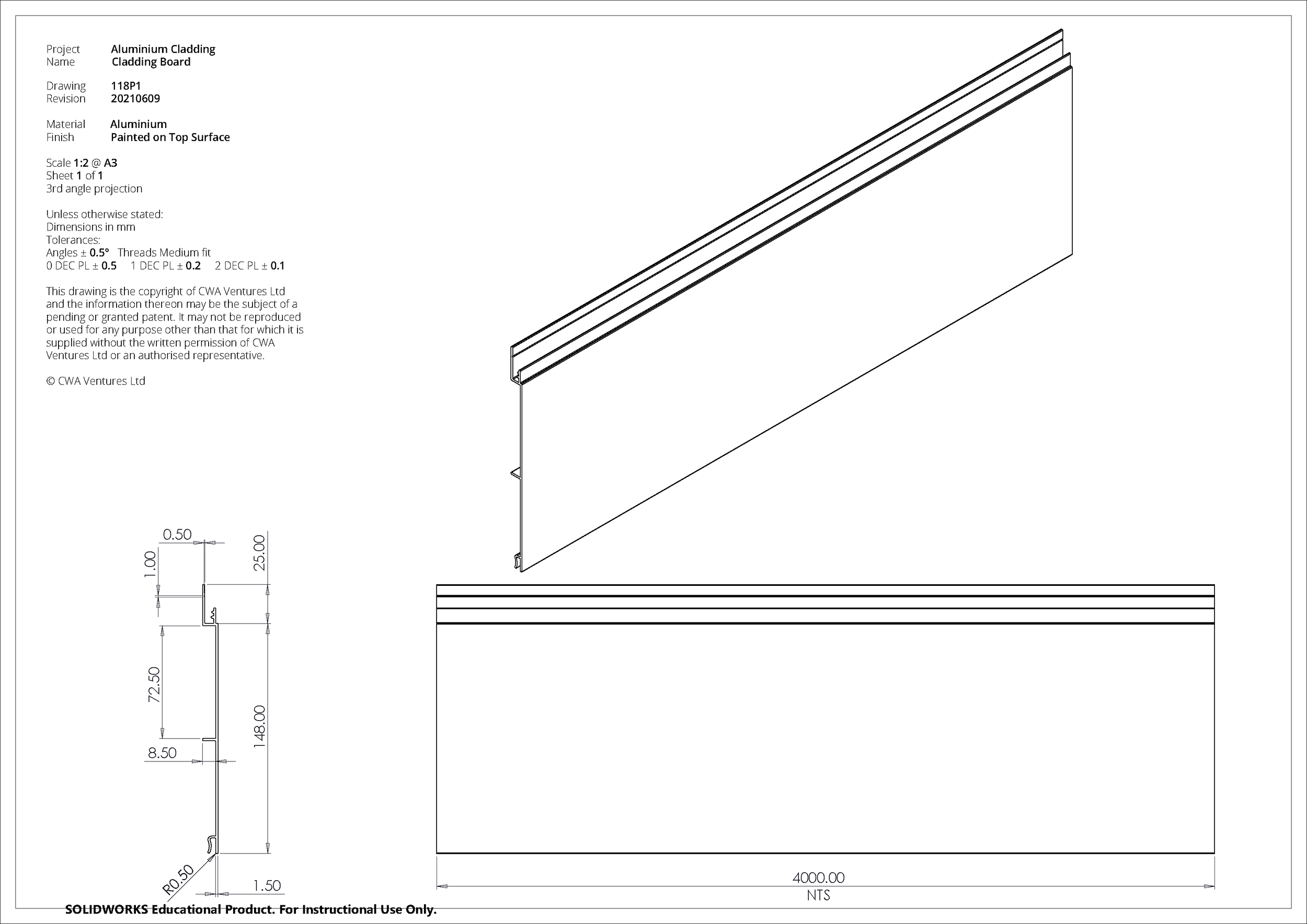

Drawings

Once the design was decided upon, technical drawings were made and sent to the supplier for making samples.

Samples

With the samples returned to, we then tested the pieces in practice, to check the system worked in practice as well, and that the snap fit details all connected as expected. Small redesigns were sent to the supplier to make sure the pieces fit together as well as possible, but the changes were minor enough that the supplier’s moulds could be adapted rather than having to make entirely new ones, thus saving cost.

Final Design

With the design fully iterated upon, the product was released at the London Trade Expo 2021.

The final design used only three components in its most basic configuration, and minimal use of screws. Through working closely with the supplier, material use was kept to a minimum by making the thickness of the cladding profiles only 1.3 mm. Through use of snap fits, a completely screwless finish is possible, and the cladding was made easy to install. Being entirely made from aluminium, the cladding is safe for use on high rise buildings.